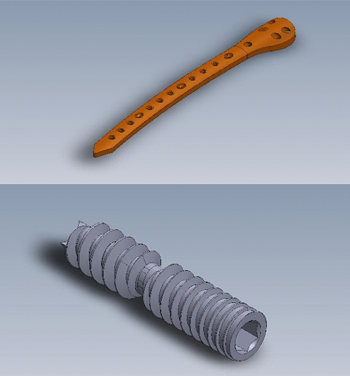

At B.D. Surgical Industries™ we believe good product design practices thread themselves throughout the entire product lifecycle. Product design is essential in creating the initial user experience and product offering, from pre-ideation user research to concept development to prototyping and usability testing. At B.D. Surgical Industries™ each product is designed by respective competitive team which specializes in CAD Designing of each product launched by us after aggressive market research by our team.

⦁ The choice of the implant material influences Rigidity, Corrosion, Biocompatibility and Tissue Receptivity, while its Surface Morphology affects its Stability within the skeleton.

⦁ All our raw material is sourced from renowed top quality providers. Special attention is paid to storage of material and is done according to appropriate ISO 13485:2016 and ASTM-B348 standards.

⦁ Each batch of raw material is tested as per ISO standards.

Any Orthopedic Implants and Orthopedic Instruments manufactured by B.D. Surgical Industries™ is being tested mechanically to check Static Fatigue, Hardness, Young Modulus and Tensile Strength of the Finished Product As per respective ISO Standards.

Computer-aided manufacturing (CAM) is a type of manufacturing method that uses computer software and automatable machinery to create products with a high degree of accuracy and precision. B.D. Surgical Industries™ have a setup of Modern machines and software technologies that enabled us to create better product with increasingly more control over the entire process. A CAM tool uses a product model created in CAD software. The former converts the computer models into a language understood by the machining tool and undertakes the production. CAM help us with product planning, development, management, storage and logistics. The foremost objective of CAM is to either create new or improve upon existing manufacturing setups to boost efficiency and reduce wastage. It does so by expediting the manufacturing process and tooling, and reducing energy requirements. The final results have a high degree of consistency, quality, and accuracy.

B.D. Surgical Industries™ have a setup of modern 2-axis and 3-axis machines from industries’ reputed manufacturer that help us to make our product of topmost accuracy and reliability. Our manufacturing setup ensures timely production and delivery of product to our customers.

B.D. Surgical Industries™ is manufacturing Best Quality Orthopedic Implants and Orthopedic Instruments as per ISO 13485:2016 & ISO 9001:2008 quality management system and we are Indian FDA approved company which gives assurance of best quality satisfaction to our customers.

Each & Every lot of Orthopedic Implants & instruments manufactured by B.D. Surgical Industries™ is packaged in Clean Room under Category of Class 10000 designed to ISO14644-1 norms under hygienic environment and packaged in HDPE milky white industrial plastic.